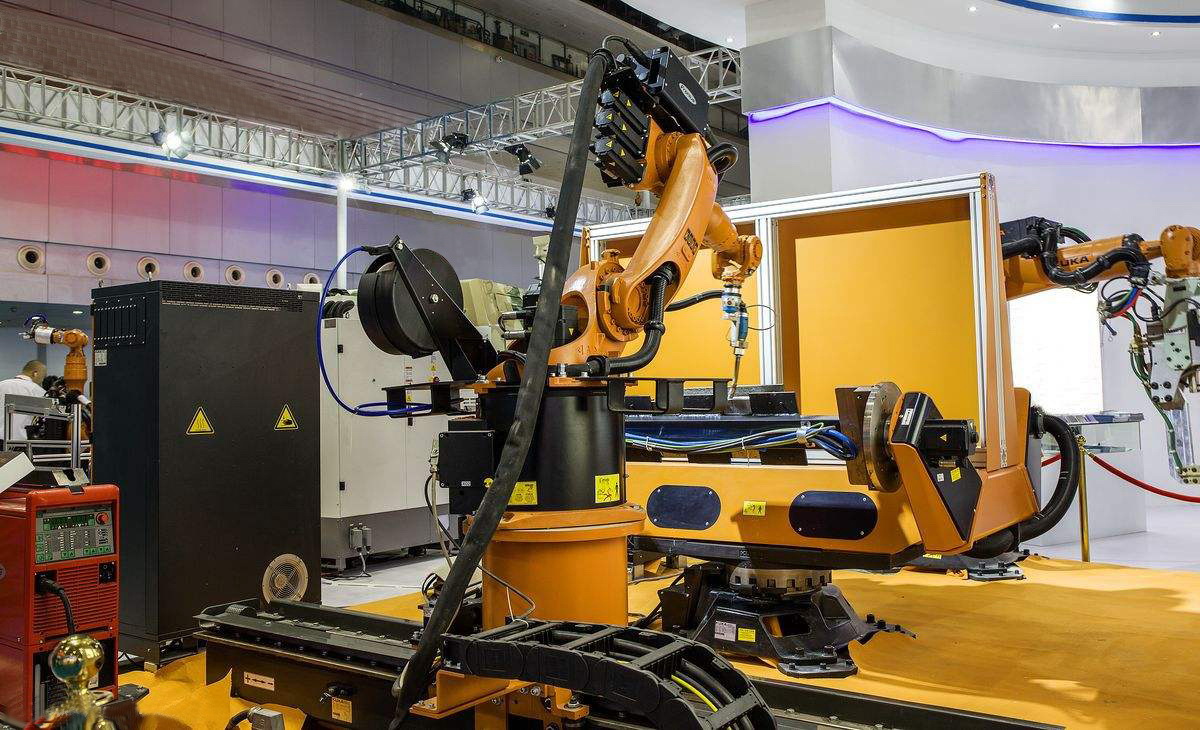

Automatic edge milling machine main function characteristics

Automatic milling machine in the current general structure on the basis of finite element structural analysis, optimization design, the product structure is more reasonable; the use of international advanced machine tool bed vibration absorption technology, can effectively reduce the vibration of the machine tool, so as to ensure the stability of the product's accuracy; the use of man-machine engineering design to make the operation and maintenance is more convenient; the use of variable-frequency technology, the product is more energy-saving According to the user's needs, the design and manufacture of special specifications of the automatic edge milling machine.

The milling head of the automatic edge milling machine adopts helical gear transmission, which is smooth; the transmission gear modulus is large, which can transmit large torque; equipped with 7.5KW motor, which is powerful and can realize powerful milling. Compared with the universal milling head, it is fixed spindle structure with large spindle diameter, good rigidity, light weight and convenient maintenance.

With domestic standard milling cutter disk, interchangeability is strong, milling head frequency conversion speed control, speed convenient, greatly improving the adaptability of product processing. If the material of the product is changed from carbon steel to stainless steel, it is necessary to reduce the milling speed, and the general milling head speed change generally adopts the hanging wheel speed change, and it is necessary to change the hanging wheel manually, and it is more troublesome to change the speed. Our products can complete the speed change just by turning the knob. Automatic speed change embodies excellent adaptability, greatly reduces the intensity of operation, and at the same time avoids replacing the hanging wheel, the operation is not careful to bring impurities and dirt into the deceleration system, resulting in early damage to the transmission system.

Improved and perfected the hydraulic system (divided into simple pressure maintaining system, high and low pressure double pump pressure maintaining system, variable pump pressure maintaining system, special hydraulic oil heat dissipation and heating system, optional) eliminated the early aging and oil leakage of hydraulic oil, which is commonly found in automatic edge milling machines.