Wireless Limit Switches Reduce Equipment Downtime and Productivity Loss Due to Proximity Sensors

Wireless Technology Drives Transformation in Factory Automation, Reducing Costs and Downtime

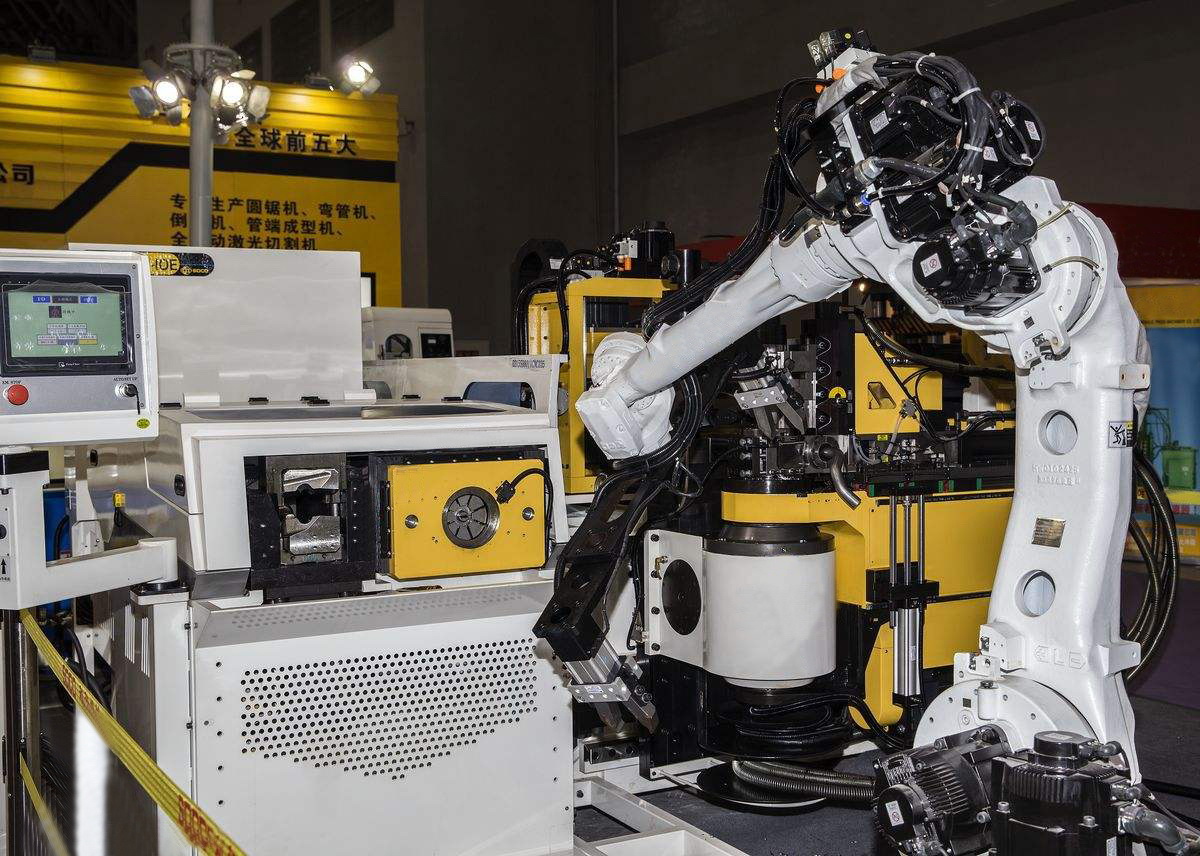

Switches and sensors can be utilized to check that parts, doors and guards are properly locked before the equipment is run. These locks are critical to ensuring production accuracy and the smooth and safe operation of the equipment. But all wired devices - whether limit switches or proximity sensors - not only have a restricted area of use, they are also prone to wear and tear and require constant maintenance.

Proximity sensors are now widely used on the factory floor simply because they are cheaper than traditional electromechanical switches. However, many manufacturers have found that proximity sensors require reactive maintenance from time to time, resulting in disruptions to the production process.

In multi-axis machining, for example, such as engine casting, the fixtures are constantly rotating the parts to be machined to get them in the right position, which causes the proximity sensor wires to be constantly moving and under stress, which leads to wear and tear on the cables and ultimately to breakage. Once the cable breaks, the equipment and workers are idle while the cable is replaced (typically 15 to 20 minutes per change). If cables are replaced every 3 months (as some manufacturers do), the cumulative loss of productivity is staggering. If you can predict when maintenance will be needed, preventive maintenance measures can prevent downtime for repairs.

Similarly, metal shavings brought down by the coolant from the machining area are in constant contact with the wires, constantly abrading the cable jackets and causing "short circuits" or continuity problems. At this point, the cable must be replaced, resulting in lost productivity.

Additionally, one of the biggest problems manufacturers face with sensors and devices is the number of connection points. Each connection point is a potential source of failure. By eliminating these connection points, manufacturers can reduce the number and duration of interruptions to their production processes.

All of these problems can be easily solved with wireless limit switches. Wireless technology (especially 802.15.4.2.4Ghz) has proven itself to be a reliable solution in a wide range of applications on the factory floor. The advantages of integrating wireless technology into switches include the fact that the switch does not consume power, but merely performs a control function - which, under normal operating conditions, can extend battery life to two years or more - and the diagnostic function built into the RF (Radio Frequency) circuitry provides a low-battery indication, allowing replacement of inoperative batteries before the workflow is forced to be interrupted. This is important because both the sensors and RF circuits consume a lot of power and require regular battery replacement.

Wireless switches can be easily retrofitted into applications that use standard wired switches or proximity sensors. Of course, whatever wireless device is used, an RF (radio frequency) signal needs to be sent and must be converted to a standard input signal (PNP, NPN or relay) available to the control system. This is accomplished through a wireless receiver installed in the control panel of the device. The output of this receiver is connected directly to the controller input card in a conventional wired fashion. The controller cannot distinguish whether the standard input is from a wireless or wired device. The only difference is that additional diagnostic inputs for monitoring battery life and signal strength are now added.

By reducing switch installation costs and providing greater application flexibility, wireless technology has revolutionized the factory automation world. By eliminating the need for cables, manufacturers can dramatically reduce maintenance costs, be free from downtime caused by connectors and cable integrity, and dramatically increase productivity. As new solutions continue to be released and wireless technology becomes more widely available, the use of wireless devices to solve application problems is sure to lead the way for new trends in factory automation technology.